Description

Welcome to Well-Tech - one of the leading manufacturers and suppliers of PCB products in China. Our factory is engaged in PCB manufacturing and offering customized high quality 94v0 pcb with ul at competitive price. High reliability, strong diversity and expert advice are our characteristics. Please contact us if you have inquiry.

Products description:

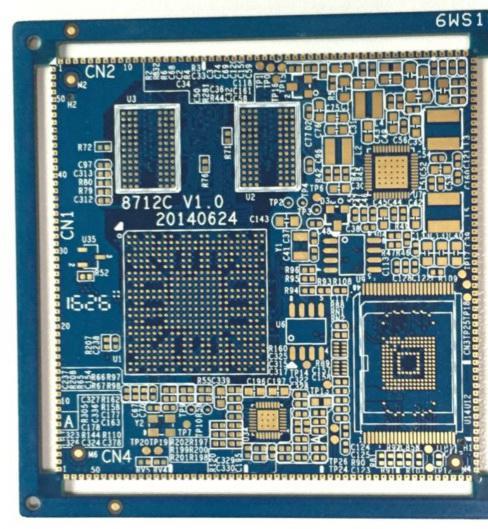

FR4 PCB

FR-4 (or FR4) is a grade designation assigned to glass-reinforced epoxy laminate sheets, tubes, rods and printed circuit boards (PCB). FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength

Well-Tech use FR4 of Shengyi,ITEQ,KB material,contact us if you have inquiries.

Products specification:

Layers: 6

Material /Laminate: FR4

Board thickness: 2.0mm

Copper weight: 1/1/1/1/1/1oz

Finishing: ENIG

Remark:Blue solder mask+half hole+impedance control

Properties

Typical physical and electrical properties of FR-4 are as follows. The abbreviations LW (lengthwise, warp yarn direction) and CW (crosswise, fill yarn direction) refer to the conventional perpendicular fiber orientations in the XY plane of the board (in-plane). In terms of Cartesian coordinates, lengthwise is along the x-axis, crosswise is along the y-axis, and the z-axis is referred to as the through-plane direction.

|

Parameter |

Value |

|

Specific gravity/density |

1.850 g/cm3 (3,118 lb/cu yd) |

|

Water absorption |

−0.125 in < 0.10% |

|

Temperature index |

140 °C (284 °F) |

|

Thermal conductivity, through-plane |

0.29 W/(m·K),[1] 0.343 W/(m·K)[2] |

|

Thermal conductivity, in-plane |

0.81 W/(m·K),[1] 1.059 W/(m·K)[2] |

|

Rockwell hardness |

110 M scale |

|

Bond strength |

> 1,000 kg (2,200 lb) |

|

Flexural strength (A; 0.125 in) - LW |

> 415 MPa (60,200 psi) |

|

Flexural strength (A; 0.125 in) - CW |

> 345 MPa (50,000 psi) |

|

Dielectric breakdown (A) |

> 50 kV |

|

Dielectric breakdown (D48/50) |

> 50 kV |

|

Dielectric strength |

20 MV/m |

|

Relative permittivity (A) |

4.8 |

|

Relative permittivity (D24/23) |

4.8 |

|

Dissipation factor (A) |

0.017 |

|

Dissipation factor (D24/23) |

0.018 |

|

Dielectric constant permittivity |

4.70 max., 4.35 @ 500 MHz, 4.34 @ 1 GHz |

|

Glass transition temperature |

Can vary, but is over 120 °C |

|

Young\'s modulus - LW |

3.5×106 psi (24 GPa) |

|

Young\'s modulus - CW |

3.0×106 psi (21 GPa) |

|

Coefficient of thermal expansion - x-axis |

1.4×10−5 K−1 |

|

Coefficient of thermal expansion - y-axis |

1.2×10−5 K−1 |

|

Coefficient of thermal expansion - z-axis |

7.0×10−5 K−1 |

|

Poisson\'s ratio - LW |

0.136 |

|

Poisson\'s ratio - CW |

0.118 |

|

LW sound speed |

3602 m/s |

|

SW sound speed |

3369 m/s |

|

LW Acoustic impedance |

6.64 MRayl |

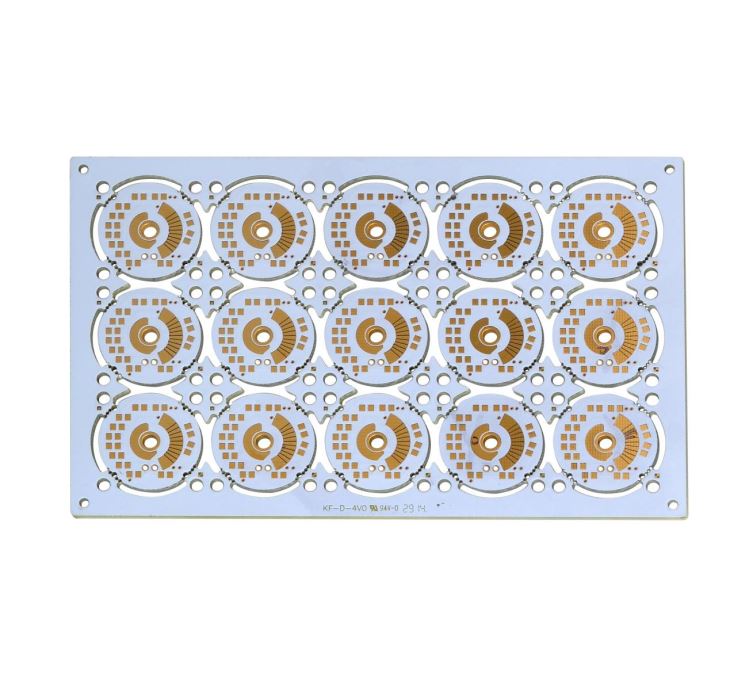

Applications

FR4 PCBs are used in many industries,like consumer electronics, telecom & networking, new energy, public security surveillance, industrial, medical, automotive and etc.